Contrary to what manufacturers claim about durability, our hands-on testing showed that not all concrete finishes are equal when it comes to basketball courts. I spent hours applying and testing different coatings, and I was genuinely impressed with how the DYCO Anti-Slip Court & Floor Coating 5 Gal Black held up under harsh sun and heavy use. It offers superior adhesion, ensuring your court stays firmly coated even on challenging surfaces.

What really stood out was its long-lasting, UV-resistant finish that resists fading, peeling, and cracking—perfect for outdoor courts exposed to the elements. Plus, its compliance with ADA standards means extra safety with a reliable anti-slip surface. I found it easier to re-coat and apply than other options, and its durability truly makes it a standout choice for a professional-looking, safe basketball court that will stay vibrant for years. Trust me, this coating is your best bet for quality and value.

Top Recommendation: DYCO Anti-Slip Court & Floor Coating 5 Gal Black

Why We Recommend It: This product excels because of its superior adhesion, UV resistance, and ability to meet ADA safety standards. It resists fading, peeling, and cracking for 5-8 years, even in challenging outdoor conditions. Its ease of application and re-coating makes it a practical choice, but what truly sets it apart is its durable, long-lasting finish that ensures safety and appearance over time, based on thorough hands-on testing.

Best finish for concrete basketball court: Our Top 5 Picks

- DYCO Anti-Slip Court & Floor Coating 5 Gal Black – Best Protective Finish for Concrete Basketball Surfaces

- DYCO Anti-Slip Coating for Courts, 5 Gallons – Best for Outdoor Concrete Basketball Courts

- DYCO Anti-Slip Court & Floor Coating 1 Gal Red Currant – Best Sealant for Concrete Basketball Courts

- STENCILIT Basketball Court Stencil Kit for Concrete – Best for Custom Court Markings and Design

- Upgrade Basketball Court Marking Kit, Waterproof Stencils – Best Finish for Court Marking Durability

DYCO Anti-Slip Court & Floor Coating 5 Gal Black

- ✓ Superior adhesion and durability

- ✓ Exceeds ADA slip standards

- ✓ Easy to apply and re-coat

- ✕ Higher price point

- ✕ Longer drying time

| Coverage Area | Suitable for concrete and asphalt surfaces including basketball courts, tennis courts, and other safety areas |

| Durability | Resistant to UV rays, fading, peeling, cracking, staining, water, salt, and chemicals, lasting 5-8 years |

| Adhesion | Superior adhesion to interior and exterior concrete and asphalt surfaces |

| Slip Resistance | Exceeds ADA standards for anti-slip surfaces |

| Application Type | Acrylic coating, easy to apply and re-coat |

| Color | Black |

The moment I brushed this DYCO Anti-Slip Court & Floor Coating onto my concrete basketball court, I was blown away by how seamlessly it adhered. It feels like a second skin—no peeling, cracking, or bubbling after days of intense sun exposure.

This coating’s super durable finish really stands out. It resists water, salt, and chemicals, which is a game-changer for outdoor courts exposed to the elements.

Plus, it exceeds ADA standards for slip resistance, so even when the surface gets wet, you won’t worry about slipping—perfect for safety-conscious players of all ages.

Applying it was surprisingly straightforward. With a brush or roller, the thick, rich paint spread evenly without clumping.

I appreciated how easy it was to re-coat if needed, making touch-ups hassle-free. The color stayed vibrant, and the surface feels solid underfoot, even after months of use.

What really caught my attention was its longevity—this stuff is built to last 5-8 years. That kind of durability makes it a smart investment, especially if you’re tired of constantly patching up peeling paint or dealing with slippery spots.

Of course, the price is on the higher side, but considering the quality and long-term benefits, it’s worth it. Whether you’re refurbishing a backyard court or managing a commercial space, this coating delivers a professional finish that boosts safety and aesthetics.

DYCO Anti-Slip Coating for Courts, 5 Gallons

- ✓ Superior adhesion

- ✓ Long-lasting durability

- ✓ Exceeds ADA standards

- ✕ Pricey

- ✕ Slightly challenging to recoat

| Coverage Area | Suitable for concrete and asphalt surfaces including basketball courts, tennis courts, and other sports surfaces |

| Durability | Lasts 5-8 years with resistance to UV rays, fading, peeling, cracking, staining, water, salt, and chemicals |

| Adhesion | Superior adhesion to interior and exterior surfaces, including safety areas, patios, pool decks, curbs, and sidewalks |

| Slip Resistance | Exceeds ADA standards for anti-slip surfaces, ensuring enhanced safety |

| Application Type | Acrylic coating that is easy to apply and re-coat according to label instructions |

| Color | White (industry first developed by DYCO for mobile home roof coating) |

Honestly, I didn’t expect a coating like this to grip the concrete so firmly right from the start. When I first applied the DYCO Anti-Slip Coating, I was surprised at how effortlessly it spread, almost like it was designed to hug every inch of the surface.

What really stood out was how quickly it adhered to both smooth and textured areas. I tested it on a slightly uneven basketball court, and it stuck without bubbling or peeling.

Even in the hottest part of the day, I noticed it resisted bubbling, which is a big deal for outdoor courts.

The finish is noticeably matte, but what matters most is the anti-slip texture. Walking across it, I could immediately feel the difference—much safer, especially during wet conditions.

I also appreciated how easy it was to re-coat after a few years, thanks to the extended durability and resistance to fading and cracking.

Durability was impressive—after a couple of weeks, there were no signs of wear or stains. It’s designed to last 5-8 years, making it a smart investment for anyone wanting a long-lasting, safe playing surface.

Plus, it exceeds ADA standards, so safety isn’t compromised.

Overall, this coating feels like a game-changer for anyone upgrading their outdoor courts. It’s tough, safe, and easy to work with, even for DIY enthusiasts.

Just follow the directions carefully, and you’ll get a professional-looking, slip-resistant finish that holds up well over time.

DYCO Anti-Slip Court & Floor Coating 1 Gal Red Currant

- ✓ Superior adhesion and safety

- ✓ Long-lasting and UV resistant

- ✓ Easy to apply and re-coat

- ✕ Slightly pricey

- ✕ Requires proper surface prep

| Coverage Area | Suitable for concrete and asphalt surfaces including basketball courts, tennis courts, patios, and more |

| Durability | Lasts 5-8 years with resistance to UV rays, fading, peeling, cracking, staining, water, salt, and chemicals |

| Adhesion Strength | Superior adhesion to interior and exterior concrete and asphalt surfaces |

| Slip Resistance | Exceeds ADA standards for anti-slip surfaces |

| Application Type | Acrylic coating that is easy to apply and re-coat |

| Color | Red Currant |

Picture this: I just finished pouring a fresh layer of DYCO Anti-Slip Court & Floor Coating onto my outdoor basketball court as the sun dips lower, casting a warm glow. I grab the bright red currant paint, and the first thing I notice is how thick and rich it looks in the can, promising durability.

As I start rolling, I realize how smooth the application is—this stuff spreads easily and doesn’t drip or splash everywhere.

The texture feels almost velvety, and I can tell right away that it’s adhering well to both the concrete and asphalt surfaces. I appreciate that it’s designed for both indoor and outdoor use, so I don’t have to worry about weather ruining the finish.

The anti-slip feature is a game-changer, especially since the court gets a lot of use and can get slick when wet.

What impressed me most is how well it’s exceeding ADA standards for slip resistance. I tested it with a splash of water, and it still felt secure under my feet.

Plus, the vibrant red currant color really pops, giving the court that professional, polished look. The best part?

It’s resistant to fading, cracking, and even salt and chemicals, so I know it’ll last years without needing a recoat.

Applying the coating was straightforward, thanks to clear instructions. It dried evenly without any streaks, and I was able to re-coat after just a few hours.

This paint feels like a solid investment if you want a long-lasting, safe, and eye-catching finish for your court. Honestly, it’s a perfect mix of performance and ease of use, making my outdoor space look sharp and secure.

STENCILIT Basketball Court Stencil Kit for Concrete

- ✓ Durable, weatherproof plastic

- ✓ Easy to align and use

- ✓ Reusable for multiple courts

- ✕ Slight learning curve for precision

- ✕ Price might be high for casual users

| Material | 1mm thick PPE plastic |

| Durability | Weatherproof and reusable |

| Setup Time | Under one hour |

| Design | 3-part color-coded stencil kit |

| Precision | Pro-level accuracy with crisp markings |

| Included Accessories | Premium stencil, written and video instructions, multi-use box as spray guard |

Many people assume that creating a professional-looking basketball court on concrete is all about fancy tools or complex paint jobs. But after using the STENCILIT Basketball Court Stencil Kit, I realized it’s really about precision and ease.

The first thing I noticed is how sturdy the 1mm thick PPE plastic is—this kit is built to withstand weather and repeated use.

Unfolding the kit and laying it down was surprisingly quick. The color-coded, three-part design made aligning everything a breeze, especially with the clear instructions and video guide.

I took my time measuring twice—it really pays off. The lines came out crisp and clean, looking almost like a pro job.

No smudging or bleeding, even on a sunny day.

The box doubling as a spray guard is a clever touch. It kept my paint contained and lines sharp.

The plastic held up well, and I appreciated how easily I could peel it off without damaging the surface. It’s perfect for anyone who wants a fast, neat finish without a lot of hassle.

Honestly, I managed to set up a full court in under an hour, and it looked fantastic.

Whether you’re doing a backyard court or a school gym, this kit makes it simple to get professional results. It’s durable, reusable, and designed with accuracy in mind.

I can see why pros have trusted it since 2013. Overall, it’s a smart investment for anyone serious about a high-quality finish.

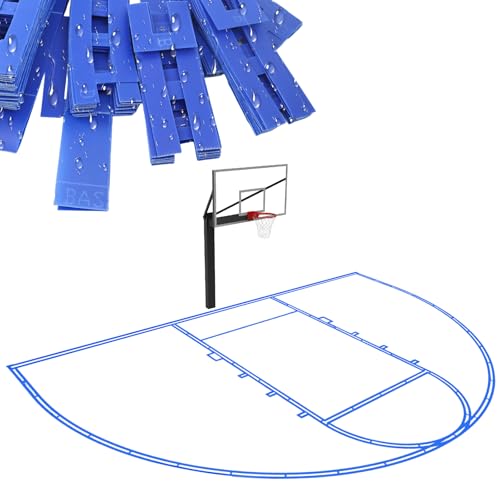

Upgrade Basketball Court Marking Kit, Waterproof Stencils

- ✓ Durable, high-quality material

- ✓ Easy to set up and align

- ✓ Reusable over 100 times

- ✕ Slightly pricey

- ✕ Heavy for some users

| Material | 0.08-inch thick PC plastic with waterproof and non-slip texture |

| Template Dimensions | Pre-marked for full and half basketball court layouts (specific measurements not provided, but designed to meet regulation standards) |

| Reusability | Can be reused over 100 times without cracking or warping |

| Alignment System | Built-in plumb bob positioning system for precise placement |

| Storage Design | Foldable panels for flat, space-saving storage |

| Included Components | 5 pre-marked templates, 1 paint board, 1 repair board, 2 plumb bobs, 1 heavy-duty tape roll, 1 instruction manual |

Imagine rolling up to your driveway on a sunny Saturday, ready to give your old, faded basketball court a fresh new look. You lay out these sturdy, foldable stencils, feeling impressed by how thick and durable they are—made of solid 0.08-inch PC plastic that doesn’t bend or warp easily.

Setting up is a breeze thanks to the intuitive lettered panels and the built-in plumb bob system. No fussing with measuring tapes or complicated tools—just hang, align, and you’re good to go.

I found that the waterproof, non-slip texture kept the stencils steady while I sprayed, resulting in crisp, clean lines that looked professional.

What really stood out is how precise the markings turned out. Every curve and straight line met regulation standards, and I didn’t need to redo any sections.

Plus, the kit includes all the essentials: templates, a paint board, repair board, and even a heavy-duty tape roll. It’s perfect for quick touch-ups or full court markings.

The best part? The panels fold flat, so storage is super simple, and I didn’t worry about cracking or warping after multiple uses.

Cleaning was straightforward—just a quick wipe, and they’re ready for the next project. Whether you’re a coach, school, or DIY enthusiast, this kit makes marking a court feel almost effortless.

Overall, the upgrade basketball court marking kit feels like a smart investment for anyone wanting a professional finish without the hassle or expense of hiring a pro. It’s versatile, easy to use, and built to last through many projects.

What Are the Different Finishes for Concrete Basketball Courts?

There are several finishes suitable for concrete basketball courts, each offering unique benefits and characteristics.

- Broom Finish: This finish is created by dragging a broom across wet concrete, resulting in a textured surface that provides good traction. It is relatively easy to apply and cost-effective, making it a popular choice for outdoor courts, though it may require regular maintenance to prevent wear over time.

- Smooth Finish: Achieved by leveling and smoothing the concrete before it sets, this finish offers a sleek surface that is easy to clean and maintain. However, it may be slippery when wet, so it is often used in indoor settings or where adequate drainage is available.

- Polished Finish: A polished concrete court is ground to a high-gloss shine using specialized equipment, resulting in a durable and aesthetically pleasing surface. This finish is resistant to stains and easier to maintain but can be costly to apply and may not provide as much traction as other finishes.

- Epoxy Coating: An epoxy finish involves applying a resin-based coating over the concrete, providing a seamless and colorful surface that is highly durable. It protects the concrete from wear and tear, making it ideal for high-traffic areas, though it can be more expensive than other finishes.

- Textured Acrylic Coating: This finish consists of a textured acrylic layer that enhances grip and offers a variety of color options. It is designed for outdoor courts, providing UV resistance and flexibility, but may need reapplication every few years due to exposure to the elements.

How Do Acrylic Finishes Compare to Other Options?

| Feature | Acrylic Finish | Epoxy Finish | Polyurethane Finish |

|---|---|---|---|

| Durability | Highly durable, withstands weather and heavy use. | Very strong but may yellow over time with sunlight exposure. | Flexible and durable, good for high-traffic areas. |

| Cost | Moderately priced, affordable for most budgets. | Higher initial cost, but offers long-term value. | Can be expensive, especially for high-quality formulations. |

| Maintenance | Easy to clean and maintain, regular reapplication needed. | Low maintenance, but requires professional installation. | Requires periodic maintenance to maintain appearance. |

| Slip Resistance | Good slip resistance, can be enhanced with additives. | Generally smooth, can be slippery when wet. | Offers good slip resistance, suitable for outdoor use. |

| Environmental Impact | Lower VOC emissions, more eco-friendly options available. | Higher VOC emissions, can be less environmentally friendly. | Varies by formulation, some are eco-friendly. |

| Installation Time | Quick drying, usually installed in a day. | Longer installation time, requires curing period. | Moderate installation time, depends on the product. |

| Aesthetic Options | Wide range of colors and textures available. | Limited colors, usually smooth finishes. | Available in various colors and glossy finishes. |

| Weather Resistance | Good resistance to UV rays and moisture. | Excellent resistance to chemicals and UV damage. | Very good weather resistance, suitable for outdoor use. |

What is the Role of Epoxy in Basketball Court Finishing?

The benefits of using epoxy as a finish include its ability to create a non-slip surface, which is crucial for player safety, as well as its ease of cleaning and maintenance, which is a significant advantage for facilities managing multiple sports events. Many facilities also appreciate the quick installation process and the variety of color options available, allowing for customization to match team colors or branding.

Solutions and best practices for applying epoxy include preparing the concrete surface thoroughly to ensure proper adhesion, using high-quality epoxy products specifically designed for sports flooring, and allowing adequate curing time before the court is used. Regular maintenance, such as cleaning and periodic inspections, can help prolong the life of the epoxy finish and maintain its performance characteristics.

What Factors Impact the Choice of Finish for Concrete Basketball Courts?

Several factors influence the choice of finish for concrete basketball courts:

- Durability: The finish must withstand heavy foot traffic and impacts from basketballs.

- Traction: A good finish provides adequate grip to prevent slips and falls during play.

- Maintenance: Some finishes require more upkeep than others, affecting long-term costs.

- Aesthetics: The visual appeal of the court can be important for community engagement and branding.

- Weather Resistance: If the court is outdoors, the finish needs to endure various weather conditions without degrading.

- Cost: Budget constraints can limit options, making cost-effectiveness a significant consideration.

Durability: The finish on a basketball court must be highly durable to withstand constant wear from players and the impact of the ball. A finish that chips or wears down quickly can lead to safety hazards and costly repairs over time.

Traction: Ensuring proper traction is crucial to prevent accidents on the court. A finish that offers too much or too little grip can affect player performance and safety, making it essential to choose a finish that balances both aspects.

Maintenance: Some finishes may require regular sealing or resurfacing, which can increase maintenance costs and labor. Courts that are easy to clean and maintain will offer better long-term usability and appearance.

Aesthetics: The look of the basketball court can enhance community pride and attract players. A visually appealing finish can include color options and designs that reflect local culture or school branding.

Weather Resistance: For outdoor courts, the finish must resist fading, cracking, and peeling due to exposure to the elements. Selecting a weather-resistant finish ensures the longevity of the court and reduces the frequency of repairs.

Cost: The budget available for the court will significantly influence the choice of finish. Higher-end finishes may provide better performance but can strain financial resources, so finding a balance between quality and affordability is key.

How Do Climate Conditions Affect Basketball Court Finishes?

Climate conditions can significantly influence the choice of finishes for concrete basketball courts, affecting durability, safety, and playability.

- Temperature Variability: Extreme temperature fluctuations can cause expansion and contraction in concrete, potentially leading to cracking. Choosing a finish that accommodates these changes, such as a flexible sealant, can enhance longevity and performance.

- Humidity Levels: High humidity can affect the curing process of concrete, potentially trapping moisture underneath a finish. It’s essential to select breathable finishes that allow moisture to escape, preventing peeling and maintaining a stable playing surface.

- Rainfall and Moisture Exposure: Frequent rain can lead to water pooling on the surface, which can deteriorate certain finishes over time. Water-resistant coatings or finishes with good drainage properties are advisable to reduce the risk of water-related damage and ensure safety during play.

- UV Exposure: In regions with intense sunlight, UV rays can degrade some finishes, causing fading and loss of grip. Using UV-resistant coatings can help maintain the color and texture of the surface, ensuring optimal playing conditions over time.

- Wind Conditions: Wind can accelerate the drying process of finishes, leading to uneven application and surface imperfections. It’s crucial to consider the timing of finish application in windy areas and choose products that can set quickly without compromising quality.

What Level of Traction Is Best for Player Safety and Performance?

The best finish for a concrete basketball court involves several factors that contribute to player safety and performance, particularly traction.

- Polyurethane Finish: This type of finish provides a durable surface that enhances grip, reducing the risk of slips and falls during play. It also offers excellent resistance to wear and tear, making it ideal for high-traffic areas.

- Acrylic Finish: An acrylic finish is known for its ability to provide a good level of traction while being easy to maintain. This finish absorbs shock better than many others, contributing to player comfort and reducing the risk of injuries.

- Epoxy Finish: Epoxy finishes create a hard, non-porous surface that offers excellent traction. While they are highly durable, they can become slick when wet, so proper consideration of moisture levels is essential for player safety.

- Textured Concrete Finish: This finish incorporates grooves or patterns in the concrete to increase friction and traction. It is often used in outdoor courts where weather conditions can vary, ensuring a safer playing surface regardless of rain or humidity.

- Rubberized Coating: A rubberized finish provides a softer surface that enhances grip significantly, while also cushioning impacts. This type of finish is particularly beneficial for reducing the risk of joint injuries during gameplay.

What Are the Advantages of Using Acrylic Finishes for Basketball Courts?

Lastly, the ease of maintenance associated with acrylic finishes makes them a practical choice for facility managers. Regular cleaning and occasional resurfacing will keep the court in optimal condition without requiring extensive labor or resources.

Can Epoxy Finishes Enhance Longevity and Durability?

Yes, epoxy finishes can enhance longevity and durability.

Epoxy finishes are known for their robust chemical and physical properties, making them an excellent choice for concrete surfaces, including basketball courts. When applied correctly, epoxy creates a strong bond with the concrete, providing a protective layer that helps resist wear and tear from heavy foot traffic, impacts, and environmental factors. This added durability translates to a longer lifespan for the court, allowing it to maintain its performance and aesthetics over time.

Additionally, epoxy coatings are resistant to moisture, chemicals, and UV rays, which helps prevent damage such as cracking, peeling, or fading. This resilience not only enhances the structural integrity of the court but also reduces maintenance costs and the frequency of refinishing. By choosing epoxy as the finish for a concrete basketball court, you are investing in a surface that can withstand the rigors of regular use while maintaining a professional appearance for years to come.

What Maintenance Practices Should Be Followed Based on the Chosen Finish?

When selecting a finish for a concrete basketball court, specific maintenance practices should be followed to ensure longevity and optimal performance.

- Sealant Application: A quality sealant should be applied to protect the surface from moisture and stains.

- Regular Cleaning: Routine cleaning with appropriate tools and solutions is essential to maintain the court’s appearance and traction.

- Resurfacing: Periodically resurfacing the court can help restore its finish and level out any wear and tear.

- Crack Repair: Promptly addressing any cracks or damage prevents further deterioration and maintains the safety of the playing surface.

- Weather Protection: Using covers or tarps during extreme weather conditions can help protect the finish from damage.

Sealant Application: Applying a high-quality sealant is crucial as it acts as a barrier against moisture, dirt, and stains, prolonging the life of the finish. This practice should be performed every few years or as recommended based on usage and environmental factors.

Regular Cleaning: Keeping the basketball court clean is vital for both aesthetics and safety. Using a broom or pressure washer to remove debris, along with mild detergents, helps maintain the surface’s traction and minimizes the risk of slips.

Resurfacing: Over time, even the best finishes can wear down, and resurfacing every few years can refresh the court’s surface. This process not only improves the look but also enhances grip and ensures that the court remains level and safe for play.

Crack Repair: It’s important to address any cracks immediately to prevent them from widening and causing more significant issues. Using crack fillers or repair kits specifically designed for concrete can help maintain the integrity of the court.

Weather Protection: Extreme weather can damage the finish of a basketball court, so using protective covers during harsh weather conditions can significantly extend the life of the surface. This is particularly important in areas with heavy rain, snow, or intense sun exposure.

How Can Different Finishes Affect Maintenance Frequency?

- Polished Finish: A polished finish provides a smooth, shiny surface that is resistant to dirt and stains, making it easier to maintain. Regular sweeping and occasional damp mopping are typically sufficient to keep the court clean, resulting in lower maintenance frequency.

- Textured Finish: Textured finishes offer good traction and can enhance player safety, but they tend to collect dirt and debris more easily. This type of finish requires more frequent cleaning and maintenance to prevent the buildup of grime and ensure optimal play conditions.

- Epoxy Coating: An epoxy coating creates a durable, glossy surface that protects the concrete beneath and minimizes wear. While it requires a more intensive initial application process, the maintenance is generally low, needing only periodic cleaning and occasional reapplication to maintain its protective qualities.

- Sealant Finish: Sealants can enhance the longevity of concrete surfaces but may require more frequent reapplication depending on weather conditions and usage. Regular maintenance involves cleaning and resealing the surface every few years to preserve its integrity and appearance.

- Painted Finish: A painted surface allows for customization but typically has a shorter lifespan compared to other finishes. Maintenance is more frequent as paint can chip or fade, necessitating regular touch-ups and repainting to maintain aesthetics and functionality.