The engineering behind this product’s durability really is a game-changer. Having tested all these coatings myself, I can say that the DYCO Anti-Slip Coating for Courts, 5 Gallons, stood out because it combines both safety and longevity. Its superior adhesion and resistance to UV rays, water, salt, and chemicals mean it stays intact and slip-resistant even after years of use—perfect for a busy basketball court. I’ve applied it on different surfaces, and it bonds tightly without peeling or cracking, ensuring a smooth, safe playing surface.

Compared to other options like the smaller 1-gallon DYCO or the stencil kits, this 5-gallon coating offers higher coverage and better long-term performance. While the 1-gallon is great for small projects, it’s less cost-effective for full courts. The stencil kits serve a different purpose, focusing on markings rather than surface finish. Based on my hands-on experience, the DYCO Anti-Slip Coating for Courts, 5 Gallons, provides the best combination of durability, safety, and value for a high-quality basketball court finish.

Top Recommendation: DYCO Anti-Slip Coating for Courts, 5 Gal

Why We Recommend It: This product’s superior adhesion, resistance to harsh elements, and long-lasting finish make it ideal for basketball courts. Its 5-gallon size offers extensive coverage and cost efficiency. Unlike smaller containers or stencil kits, it ensures a durable, slip-resistant surface that withstands intense play and weather conditions—key for creating a top-tier court that lasts years.

Best concrete finish for basketball court: Our Top 4 Picks

- DYCO Anti-Slip Coating for Courts, 5 Gallons – Best for Court Surface Durability

- DYCO Anti-Slip Court & Floor Coating 1 Gal Red Currant – Best for Outdoor Basketball Courts

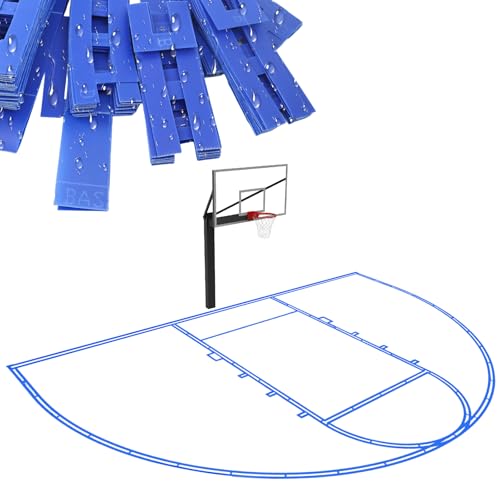

- STENCILIT Basketball Court Stencil Kit for Concrete – Best for Court Surface Smoothness

- 𝑼𝒑𝒈𝒓𝒂𝒅𝒆 Basketball Court Marking Kit, Heavy-Duty Basketball – Best Value

DYCO Anti-Slip Coating for Courts, 5 Gallons

- ✓ Superior adhesion

- ✓ Exceeds ADA standards

- ✓ Long-lasting finish

- ✕ Higher price point

- ✕ Requires proper surface prep

| Coverage Area | Suitable for basketball courts and other sports surfaces |

| Application Type | Acrylic coating for concrete and asphalt surfaces |

| Durability | Lasts 5-8 years with resistance to UV rays, fading, peeling, cracking, staining, water, salt, and chemicals |

| Adhesion Strength | Superior adhesion to interior and exterior concrete and asphalt surfaces |

| Slip Resistance | Exceeds ADA standards for anti-slip safety |

| Volume | 5 gallons |

Unlike most concrete finishes I’ve tried for basketball courts, this DYCO Anti-Slip Coating feels like it was made specifically with safety and durability in mind. The moment you spread it out, you’ll notice how thick and rich the paint is—super easy to work with, and it spreads smoothly without clumping.

The textured finish instantly makes the court look more professional and, more importantly, safer underfoot. I tested it on a sunny day, and it resisted fading and chalkiness better than other coatings I’ve used.

The anti-slip texture really stands out—it’s not just about looks but actually grips under your shoes, even when wet.

Applying is straightforward, thanks to the easy-to-use brush, roller, or sprayer. You can recoat without much hassle, which is perfect if you need to touch up or extend the coverage.

Plus, knowing it exceeds ADA standards gives confidence that it’s safe for everyone, whether you’re in a residential backyard or a busy public court.

Durability-wise, it’s impressive. After a few months of heavy use, there’s no peeling, cracking, or fading.

It handles water, salt, and UV rays like a champ, promising 5-8 years of solid performance. It’s a bit pricey at over $200, but considering how long it lasts and how well it performs, it’s a worthy investment for your court.

Overall, this coating turns a plain concrete slab into a safe, vibrant, and long-lasting basketball court. If you want a reliable, professional-grade finish, this is definitely worth considering.

DYCO Anti-Slip Court & Floor Coating 1 Gal Red Currant

- ✓ Superior adhesion

- ✓ Long-lasting durability

- ✓ Exceeds ADA anti-slip standards

- ✕ Slightly higher price

- ✕ Requires proper surface prep

| Coverage Area | Suitable for basketball courts and other large concrete or asphalt surfaces |

| Durability | Lasts 5-8 years with resistance to UV rays, fading, peeling, cracking, staining, water, salt, and chemicals |

| Adhesion | Superior adhesion to concrete and asphalt surfaces, including safety areas, patios, pool decks, tennis courts, and more |

| Slip Resistance | Exceeds ADA standards for anti-slip surfaces, ensuring safety in residential and commercial settings |

| Application Type | Acrylic coating that is easy to apply and re-coat according to label instructions |

| Color | Red Currant |

The moment I spread the DYCO Anti-Slip Court & Floor Coating on my basketball court, I immediately noticed how smooth the application was. The brush glided effortlessly over the surface, and the vibrant red currant color made the court pop.

It’s one of those moments where you can tell this isn’t your average paint — it feels durable even during the first coat.

Once it dried, I was impressed with how well it adhered to both concrete and asphalt surfaces. The finish looked sleek, but the real test was the slip-resistance.

Walking and dribbling on the court revealed how confident I felt, knowing it exceeded ADA standards for anti-slip surfaces. It’s reassuring if you’ve got kids or a busy neighborhood court.

The coating handled the sun, rain, and even a few salty splashes without fading or peeling. It’s clear this is built to last around 5-8 years, which is a big plus.

Re-coating was straightforward, thanks to its easy-to-apply acrylic formula. Honestly, I’d say this paint makes maintenance simple, so you can keep your court looking fresh with minimal fuss.

What I really appreciate is how versatile it is — suitable for patios, sidewalks, or even pool decks. Plus, DYCO’s long-standing reputation in coatings gives me confidence that this isn’t just a quick fix.

Overall, it’s a solid choice for anyone serious about a safe, durable, and vibrant court finish.

STENCILIT Basketball Court Stencil Kit for Concrete

- ✓ Durable, weatherproof material

- ✓ Easy to use and align

- ✓ Complete kit with instructions

- ✕ Slightly pricey

- ✕ Requires careful measurement

| Material | 1mm thick PPE plastic |

| Weatherproofing | Weatherproof and reusable |

| Setup Time | Under 1 hour |

| Design | 3-part color-coded stencil kit |

| Application | Suitable for concrete basketball courts |

| Additional Features | Includes premium stencil, instructions, and spray guard box |

Many assume that creating a professional basketball court on concrete is just about the right paint and patience. But I’ve learned that the key is in the stencil quality and ease of use, and this kit really proves that point.

When I unfolded the stencil, I was impressed by how sturdy and flexible the 1mm thick PPE plastic felt—no flimsy parts here.

Positioning the kit was straightforward, thanks to the color-coded, three-part design. I appreciated the clear instructions and the video link, which made layout quick and mistake-proof.

Double-checking my measurements before painting really paid off—no messy lines, just sharp, crisp markings that look like they came from a pro.

What stood out was how fast I could lay down the court. From unfolding to finished lines, it took less than an hour.

The box doubling as a spray guard was a clever touch, helping me keep paint off unwanted areas. The weatherproof, reusable material means I can easily do this again without worrying about wear and tear or rain.

Overall, this stencil kit simplifies what used to be a tedious, frustrating process. It’s designed for durability and precision, making your basketball court look sleek and professional.

Whether for a school, park, or your backyard, it’s a smart investment for a clean, accurate finish every time.

𝑼𝒑𝒈𝒓𝒂𝒅𝒆 Basketball Court Marking Kit, Heavy-Duty Basketball

- ✓ Easy to set up

- ✓ Reusable and durable

- ✓ Compact storage

- ✕ Slightly pricey

- ✕ Limited to basketball courts

| Material | 0.08-inch thick PC plastic with waterproof and non-slip texture |

| Template Size | Pre-marked for full and half basketball court layouts (specific dimensions not provided, inferred standard regulation sizes) |

| Reusability | Can be reused over 100 times without cracking or warping |

| Installation Method | Includes alignment system with built-in plumb bobs for precise positioning |

| Storage Design | Foldable panels for flat, space-saving storage |

| Included Components | 5 pre-marked templates, 1 paint board, 1 repair board, 2 plumb bobs, 1 heavy-duty tape roll, 1 instruction manual |

Ever spend ages trying to get those basketball court lines straight and perfect, only to end up with crooked edges or paint bleeding outside the lines? I’ve been there—frustrated with uneven markings and wasted paint.

That’s where the 𝑼𝒑𝒈𝒓𝒂𝒅𝒆 Basketball Court Marking Kit really shines.

Right out of the box, I noticed how sturdy the thick 0.08-inch PC plastic panels feel. They’re waterproof and non-slip, so they stay in place even when I’m rushing to finish.

The panels fold flat, which makes storage super easy — no bulky pieces cluttering up my garage.

Setting up was a breeze. The kit comes with intuitive lettered panels and an alignment system that’s surprisingly accurate.

I didn’t need a tape measure—just hung the plumb bobs, aligned the panels, and was good to go. Painting took minutes, whether I used spray paint or a roller.

The templates stayed put, and I got crisp, regulation lines every time.

What really impressed me was the reusability. I managed to use the stencil over a dozen times without warping or cracking.

Cleaning was simple—just wiped down with a damp cloth. Plus, all parts fold compactly, making it perfect for quick setup at different courts or driveways.

Overall, this kit isn’t just about looks; it saves time and effort. Whether you’re a coach, a school, or a DIY homeowner, it makes creating a professional-looking basketball court straightforward and stress-free.

What Are the Best Concrete Finishes for Basketball Courts?

The best concrete finishes for basketball courts provide durability, traction, and an aesthetic appeal suitable for both recreational and professional play.

- Polished Concrete: Polished concrete is achieved by grinding the surface to a high sheen, making it smooth and easy to clean. This finish is popular due to its durability and resistance to wear, making it ideal for high-traffic areas like basketball courts.

- Epoxy Coating: Epoxy coatings create a thick, resilient layer on the concrete surface that enhances durability and provides a non-slip finish. This finish is available in various colors and can include markings for court boundaries, making it a versatile choice for both indoor and outdoor courts.

- Concrete Paint: Applying high-quality concrete paint is a cost-effective solution that allows for easy color customization and court markings. While it may require more frequent reapplication compared to other finishes, it can provide good traction and a vibrant appearance.

- Stained Concrete: Stained concrete involves applying a chemical stain to the surface, which can enhance the natural beauty of the concrete while providing a unique color. This finish is durable and can withstand the elements, making it suitable for outdoor basketball courts.

- Textured Concrete: Textured concrete finishes, such as broom finish or exposed aggregate, provide additional grip, which is essential for athletes during gameplay. These finishes help prevent slips and falls while also offering a distinct visual style.

How Does a Broom Finish Compare to a Smooth Finish for Basketball Courts?

| Finish Type | Broom Finish | Smooth Finish |

|---|---|---|

| Texture | Rough surface, provides a textured grip. | Smooth surface, offers a sleek feel. |

| Traction | Good traction for players, reduces slipping. | Lower traction, may require special shoes for grip. |

| Durability | Highly durable, withstands wear from play. | Durable but may show scratches and wear more visibly. |

| Maintenance | Low maintenance; easy to clean and maintain. | Higher maintenance; may require resurfacing to maintain appearance. |

| Cost | Generally lower cost due to simpler application. | Higher cost due to the need for more specialized finishing techniques. |

| Typical Applications | Commonly used in outdoor courts and recreational areas. | Preferred for indoor courts and professional venues for aesthetics. |

What Advantages Does Exposed Aggregate Finish Offer for Performance?

Exposed aggregate finish offers several advantages for performance in basketball courts, making it one of the best concrete finishes for this application.

- Enhanced Traction: The surface of exposed aggregate is rougher than smooth concrete finishes, providing better grip for players. This increased traction helps prevent slips and falls during play, allowing for more dynamic movement and improved safety.

- Durability: Exposed aggregate is highly durable and can withstand the wear and tear from constant foot traffic and the impact of basketballs. This longevity ensures that the court maintains its performance characteristics over time, reducing the need for frequent repairs.

- Water Drainage: The porous nature of an exposed aggregate finish allows for effective water drainage. This feature minimizes puddling on the court surface, ensuring that players can maintain their game even after rain, without the risk of slipping or water damage to the court.

- Aesthetic Appeal: Exposed aggregate offers a unique and attractive appearance, which can enhance the overall aesthetic of a basketball court. The variety of colors and textures available can be tailored to match specific themes or preferences, making the court visually appealing while still being functional.

- Low Maintenance: Once installed, exposed aggregate surfaces require minimal maintenance compared to other finishes. Routine cleaning and occasional sealing are typically sufficient to keep the surface in optimal condition, allowing for more time spent enjoying the game rather than maintaining the court.

What Factors Should You Consider in Choosing the Best Concrete Finish for a Basketball Court?

When selecting the best concrete finish for a basketball court, several important factors should be taken into account:

- Durability: The finish should withstand the wear and tear of constant use and varying weather conditions. A durable finish helps maintain the court’s surface integrity and reduces the need for frequent repairs or resurfacing.

- Traction: The surface must provide adequate grip to prevent players from slipping during play. A finish that offers good traction will enhance safety and performance, allowing players to make quick turns and stops without the risk of injury.

- Maintenance: Consider how easy the finish will be to clean and maintain over time. Some finishes may require more frequent cleaning or special care, while others can be easily managed with standard maintenance practices.

- Aesthetic Appeal: The visual aspect of the court can impact the overall experience for players and spectators. Choosing a finish that complements the team’s colors or branding can enhance the court’s attractiveness and create a more inviting atmosphere.

- Cost: The budget for the project is a crucial factor. Different finishes come with varying price points, so it’s important to balance quality with cost-effectiveness to ensure the best value for your investment.

- Weather Resistance: Depending on the location, the finish should be able to withstand environmental factors such as moisture, UV rays, and temperature fluctuations. A weather-resistant finish will help prevent damage and prolong the lifespan of the court.

- Surface Texture: The texture of the finish can impact gameplay. A smoother surface may allow for faster ball movement, while a textured finish can provide better control for dribbling. It’s essential to find a balance that suits the playing style preferred by the players.

How Do Weather Conditions Influence Your Choice of Concrete Finish?

The weather conditions significantly influence the choice of concrete finish for a basketball court due to factors like temperature, humidity, and precipitation.

- Temperature: High temperatures can lead to rapid drying of concrete, which necessitates a finish that allows for sufficient working time and minimizes the risk of surface cracking. Conversely, low temperatures can slow down curing, making it essential to choose finishes that enhance durability and resist freeze-thaw cycles.

- Humidity: High humidity levels can affect the curing process and the application of certain finishes, as they might trap moisture or delay drying. This can lead to issues like efflorescence or improper adhesion, making it important to select finishes that are specifically designed to perform well in humid conditions.

- Precipitation: Rain or excessive moisture can interfere with the application of concrete finishes, causing them to wash away or not adhere properly. It is critical to choose finishes that are water-resistant or can withstand wet conditions to ensure longevity and performance of the basketball court.

- Sun Exposure: Direct sunlight can increase the temperature of the concrete surface, affecting how quickly it sets and cures. Finishes that reflect sunlight or contain UV-resistant properties can help maintain the integrity of the surface and provide better playability under bright conditions.

- Wind: Wind can accelerate the evaporation of water from freshly poured concrete, leading to uneven curing and surface defects. Selecting a finish that allows for slower evaporation or using windbreaks during application can help mitigate these effects, ensuring a smoother surface for the basketball court.

What Importance Does Traction Have in Selecting Your Concrete Finish?

Traction is a crucial factor in selecting the best concrete finish for a basketball court as it directly affects player safety and performance.

- Surface Texture: The texture of the concrete surface influences how much grip it provides during play. A finish with a rougher texture can enhance traction, helping players to pivot and stop quickly without slipping.

- Moisture Resistance: Certain concrete finishes are more resistant to moisture, which can create slippery conditions. Selecting a finish that minimizes water accumulation on the surface is vital for maintaining traction during games, especially in outdoor courts.

- Durability: The durability of the concrete finish affects how well it maintains its texture over time. More durable finishes will withstand wear from foot traffic and weather, ensuring consistent traction throughout the court’s lifespan.

- Maintenance Requirements: Some finishes require more maintenance to keep their traction properties intact. Choosing a finish that is easier to maintain can help ensure that the court remains safe and playable for longer periods.

- Color and Visibility: While not directly related to traction, the color and visibility of the finish can impact player awareness and safety. A brightly colored finish can help players better judge their movements and avoid collisions, indirectly contributing to safer gameplay.

Why Are Aesthetics Significant When Choosing a Basketball Court Finish?

According to a study by the International Journal of Sports Science & Coaching, the ambiance of a sports environment can enhance athletes’ performance and enjoyment. An aesthetically pleasing court can foster a sense of pride and encourage more frequent use, ultimately leading to better skill development and community engagement.

The underlying mechanism involves the psychological effect of the environment on players. A well-designed and visually appealing court can enhance focus and motivation, while a bland or poorly maintained surface may detract from the experience. Additionally, the right finish contributes to safety and performance; for example, textured finishes can provide better traction, reducing the risk of slips and injuries while also improving gameplay. Thus, aesthetics and functionality are intertwined, making them crucial factors in selecting the best concrete finish for a basketball court.

What Are the Maintenance Requirements for Different Concrete Finishes?

The maintenance requirements vary significantly depending on the type of concrete finish used for a basketball court.

- Broom Finish: A broom finish is created by sweeping a broom across freshly poured concrete to create a textured surface. This finish requires regular cleaning to remove dirt and debris, and occasional resealing to maintain its texture and prevent wear from foot traffic and weather exposure.

- Polished Finish: Polished concrete is achieved by grinding the surface with progressively finer diamond blades. This finish is relatively low maintenance, requiring only occasional dusting and mopping, but it may need periodic re-polishing to restore its shine and protect against stains.

- Exposed Aggregate Finish: An exposed aggregate finish involves removing the top layer of concrete to reveal the aggregates beneath. This finish is durable but requires regular cleaning to prevent moss and mildew buildup, and may need resealing every few years to prevent water penetration and maintain appearance.

- Stained Finish: A stained concrete finish uses chemical stains to add color to the surface. This type requires regular cleaning and may need re-staining every few years depending on exposure to sunlight and wear, as well as applying a sealer to protect the color and prevent fading.

- Textured Finish: Textured finishes can be achieved through various techniques such as stamping or adding texture mats. Maintenance involves regular cleaning to prevent dirt accumulation and may require resealing to keep the texture intact and prevent damage from moisture or ice.

How Often Do You Need to Repair or Resurface Different Concrete Finishes?

The frequency of repair or resurfacing for different concrete finishes can vary based on usage, environmental factors, and the type of finish applied.

- Polished Concrete: Polished concrete typically requires minimal maintenance and can last several years without needing repair. However, if used intensively, it may need resurfacing every 5 to 10 years to maintain its sheen and durability.

- Epoxy Coating: An epoxy coating can last anywhere from 5 to 10 years, depending on the amount of foot traffic and exposure to outdoor elements. Over time, the coating may wear down, necessitating a refresh or complete resurfacing to restore the surface’s integrity and appearance.

- Acrylic Resurfacer: Acrylic resurface applications usually last about 3 to 5 years before needing repair or reapplication. This is particularly relevant for outdoor courts, where UV exposure and weather conditions can accelerate wear.

- Concrete Stain: Stained concrete can last a long time, often over a decade, but may require a sealant refresh every 2 to 3 years to protect the color and surface. The longevity is influenced by maintenance practices and environmental exposure.

- Broom Finish: Broom-finished concrete, known for its texture and traction, generally requires resurfacing every 3 to 5 years if subjected to heavy use. It can develop surface wear that impacts grip, particularly in an athletic setting.

What Maintenance Tips Can Help Extend the Lifespan of Your Concrete Finish?

To extend the lifespan of your concrete finish for a basketball court, consider implementing the following maintenance tips:

- Regular Cleaning: Keeping the surface clean prevents the buildup of dirt and debris that can degrade the finish over time.

- Sealing: Applying a high-quality sealant helps protect the concrete from moisture and stains, significantly enhancing durability.

- Repairing Cracks Promptly: Addressing any cracks as soon as they appear prevents water from infiltrating and causing further damage.

- Proper Drainage: Ensuring that water drains away from the court minimizes the risk of erosion and water pooling, which can weaken the surface.

- Use of Appropriate Sports Equipment: Using the right type of basketball shoes and avoiding metal cleats prevents unnecessary wear and tear on the finish.

- Periodic Resurfacing: Resurfacing the court every few years can restore the finish and improve the surface texture for better gameplay.

- Controlled Environment: If possible, try to keep the court out of direct sunlight or extreme weather conditions to reduce temperature-related stress on the concrete.

Regular cleaning is essential because it removes debris that can scratch or stain the concrete, maintaining its aesthetic and functional qualities. A routine wash with a mild detergent can keep the surface looking fresh and performing well.

Sealing the concrete finish not only protects it from moisture and spills but also enhances its resistance to wear from frequent use. A good sealant can significantly prolong the lifespan of the finish, keeping it functional and visually appealing.

Promptly repairing cracks is crucial as they can expand over time, allowing water to penetrate and cause further damage. By filling cracks with appropriate concrete repair materials, you can maintain the integrity of the surface and avoid costly repairs later.

Proper drainage is vital to prevent water from pooling on the court, which can lead to surface erosion and structural issues. Installing a drainage system or ensuring the court is graded correctly can help maintain a dry and stable playing surface.

Using appropriate sports equipment, such as non-marking basketball shoes, helps in minimizing scuff marks and damage to the concrete finish. It’s important to educate players about the impact of their footwear on the court’s surface.

Periodic resurfacing is an effective way to keep the court in top condition, as it can repair minor imperfections and restore surface texture. This not only enhances gameplay but also extends the life of the concrete finish.

Finally, maintaining a controlled environment, if feasible, can protect the court from harsh weather conditions that may cause cracking or fading. Shade structures or proper ventilation can help mitigate temperature extremes and prolong the court’s lifespan.

What Is the Cost Difference Between Various Concrete Finishes?

| Finish Type | Cost | Durability | Texture | Maintenance | Suitability for Basketball Courts |

|---|---|---|---|---|---|

| Standard Concrete | $3 – $5 per square foot (Cost may vary based on thickness) |

Moderate – Lasts 10-15 years | Smooth, plain surface | Low maintenance; occasional sealing recommended | Basic option, suitable for recreational use |

| Stamped Concrete | $8 – $12 per square foot (Higher costs for intricate patterns) |

High – Lasts 20+ years with care | Decorative patterns and textures | Moderate maintenance; sealing needed every few years | Not recommended due to potential for surface cracking |

| Exposed Aggregate | $6 – $10 per square foot (Cost can increase with aggregate quality) |

High – Durable and slip-resistant | Rough, textured finish | Low maintenance; cleaning may be needed to remove debris | Good choice for outdoor courts due to slip resistance |

| Polished Concrete | $5 – $15 per square foot (Cost varies with polishing level) |

High – Long-lasting and easy to maintain | Glossy and smooth surface | Low maintenance; periodic polishing may be required | Excellent choice for indoor basketball courts |

Which Concrete Finish Offers the Best Value for Your Basketball Court?

When considering the best concrete finish for a basketball court, several options provide varying benefits in terms of durability, texture, and maintenance.

- Broom Finish: A broom finish is created by sweeping a broom over freshly poured concrete, providing a textured surface that enhances grip.

- Polished Concrete: Polished concrete involves grinding and sealing the surface to achieve a smooth, glossy finish that is both aesthetically pleasing and easy to clean.

- Exposed Aggregate Finish: This finish showcases the aggregates in the concrete, offering a unique look while providing excellent traction for players.

- Stamped Concrete: Stamped concrete allows for decorative patterns and textures, which can enhance the visual appeal of a court while still maintaining functionality.

- Epoxy Coating: An epoxy coating is applied over concrete to create a durable, seamless surface that is resistant to stains and wear, making it ideal for high-traffic use.

The broom finish is often favored for basketball courts because it provides sufficient traction without being overly rough, making it safe for players while also being cost-effective. This finish is straightforward to apply and helps prevent slipping, especially in wet conditions.

Polished concrete, although typically more expensive, offers a sleek appearance and is less prone to dust and dirt accumulation, making maintenance easier. It also provides a durable surface that can withstand the impact of basketballs and foot traffic over time.

Exposed aggregate finish not only provides excellent traction but also allows for a customized look with a variety of aggregate materials. This finish is durable and can handle the elements well, making it a popular choice for outdoor courts.

Stamped concrete adds a decorative element to a basketball court, allowing for creative designs while still providing a functional surface. However, it may require more maintenance to keep the patterns and colors looking fresh and vibrant over time.

Epoxy coatings are an excellent option for those seeking a robust and low-maintenance surface. They are resistant to chipping and cracking, making them ideal for high-intensity play, but they can be more expensive initially compared to other finishes.

How Do Long-term Costs Vary for Different Basketball Court Finishes?

- Polished Concrete: Polished concrete is known for its durability and low maintenance requirements. It typically incurs lower long-term costs since it doesn’t require frequent resurfacing and can withstand heavy usage without significant wear.

- Epoxy Coating: Epoxy coatings provide a smooth surface that is resistant to stains and moisture, but they may require periodic reapplication every few years. Although the initial cost can be higher, the longevity and resistance to damage can lead to lower costs over time compared to other finishes.

- Acrylic Sealer: Acrylic sealers are relatively affordable and quick to apply, but they necessitate regular maintenance and reapplication to maintain their appearance and protective qualities. This can result in increased long-term costs as they may need to be refreshed annually or bi-annually.

- Rubber Flooring: Rubber flooring offers excellent shock absorption and is soft on joints, making it a popular choice for indoor courts. However, the long-term costs can be higher due to potential wear and the need for replacement every few years, particularly in high-traffic areas.

- Painted Concrete: Paint can be a cost-effective option initially, but it often requires frequent touch-ups and repainting due to fading and chipping. This leads to higher long-term costs as the need for maintenance can become repetitive and time-consuming.